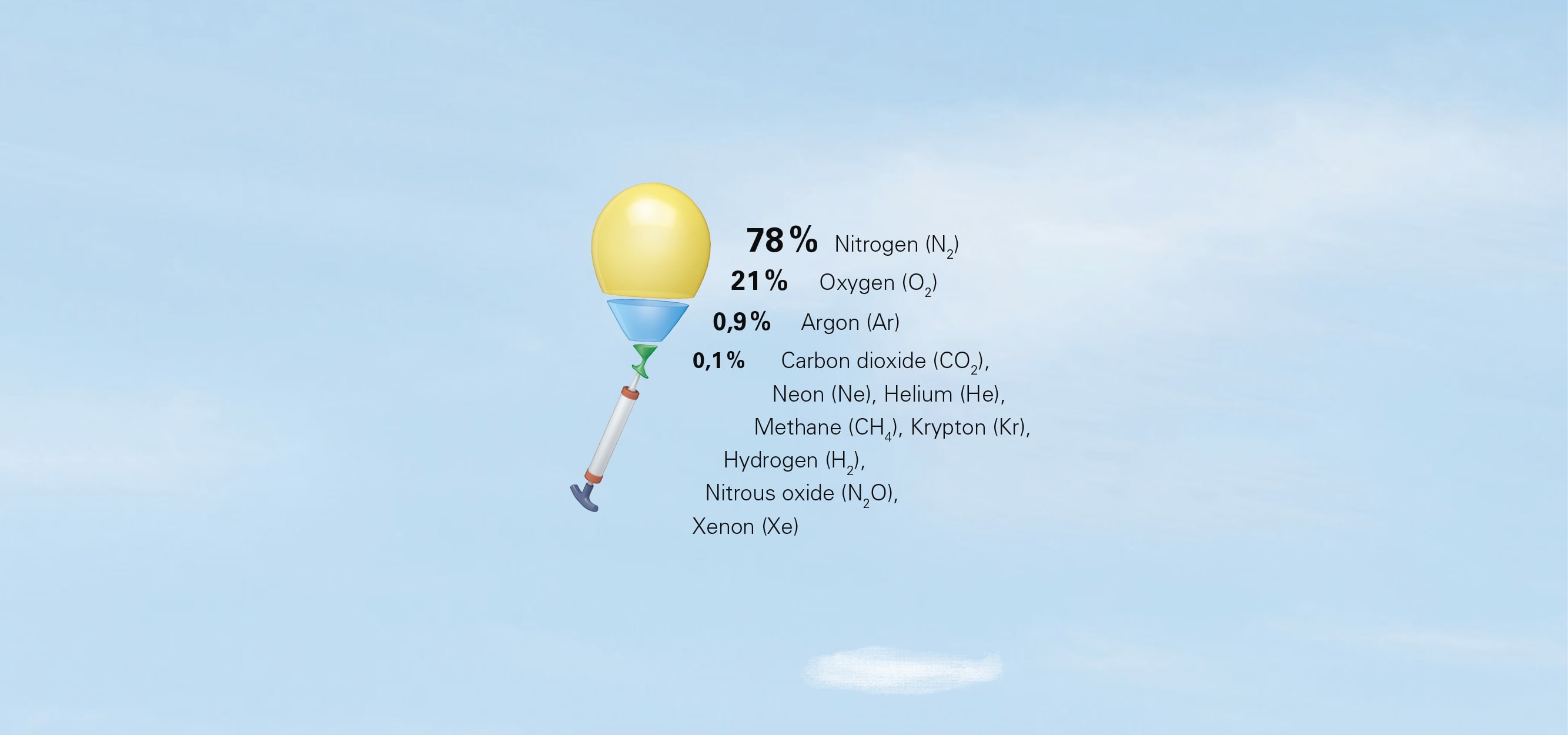

Industrial operations require oxygen, nitrogen, argon, xenon, neon and krypton, along with carbon dioxide, acetylene, hydrogen and helium, and a wide variety of gas mixtures. At Messer we call these gases Gases for Life. They are produced in large scale industrial plants and are just as important as water and electric power for many manufacturing processes, which make everyday products.

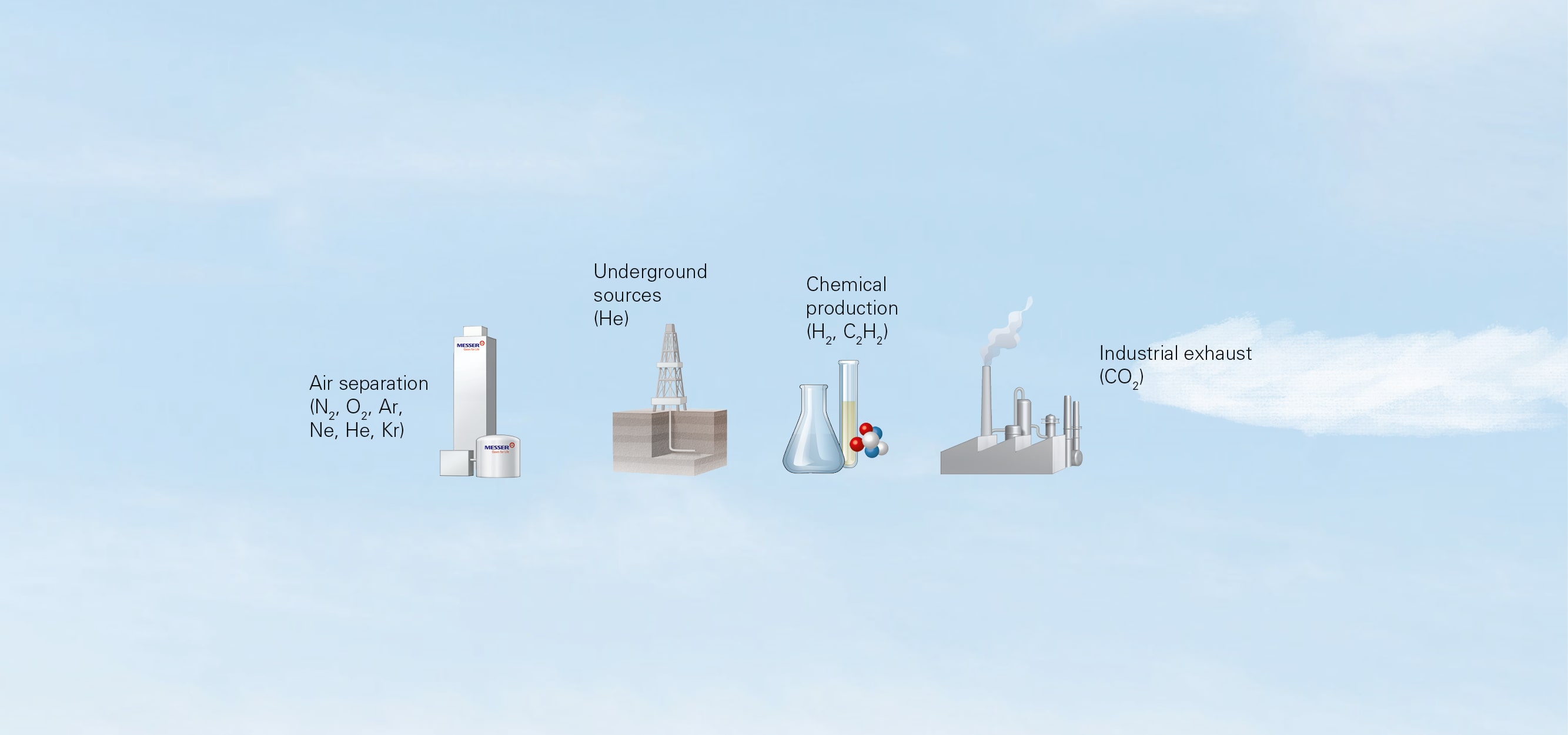

Oxygen, nitrogen, argon, xenon, neon and krypton are produced from the air. Carbon dioxide is primarily collected from the exhaust of industrial operations and cleaned. In some cases it is also produced from natural underground sources. Hydrogen and acetylene are produced chemically. Helium is produced from underground sources.

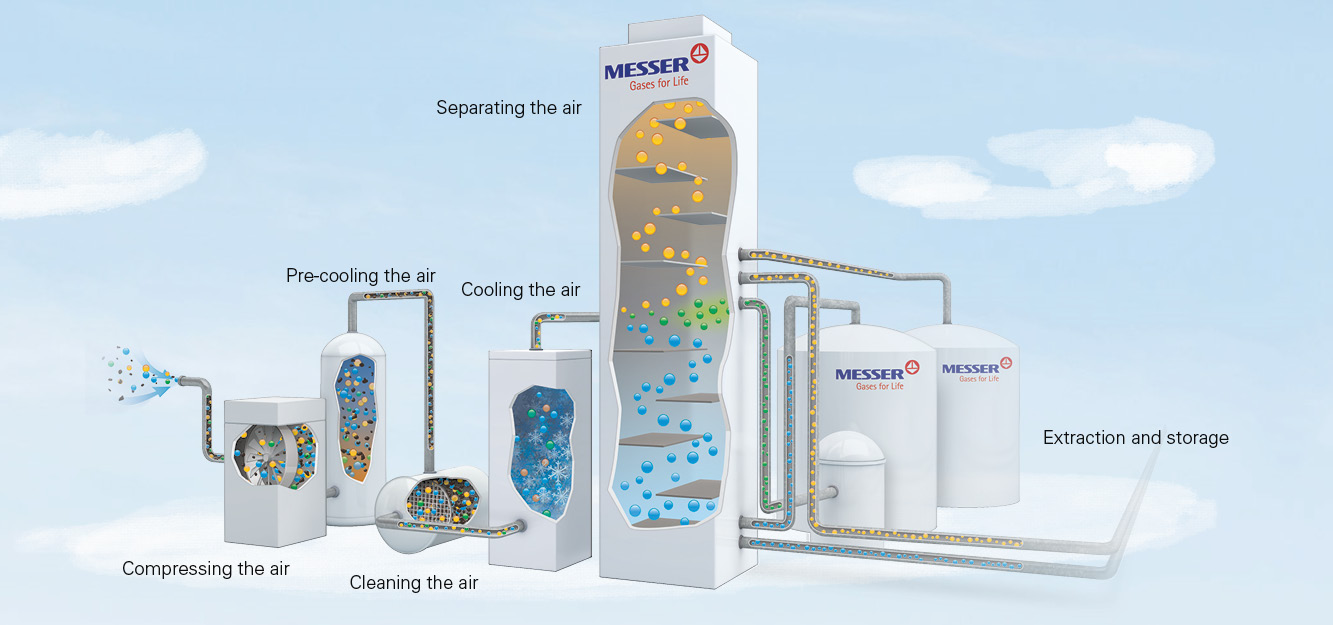

In order to produce these gases, we use air separation units which can reach 60 metres high or more. Inside them, a physical process takes place which separates the air into its components. This process, which is also known as low-temperature rectification, basically works as follows:

Air is

- filtered (dust is removed) and compressed to about six bars

- pre-chilled with cooling water

- dried and stripped of all CO2 in a molecular sieve

- cooled below minus 175 degrees Celsius and liquefied in the main heat exchanger

- separated into liquid or gaseous oxygen and nitrogen in a separation column

- also separated into liquid argon

The gases are stored in tanks in liquid form.

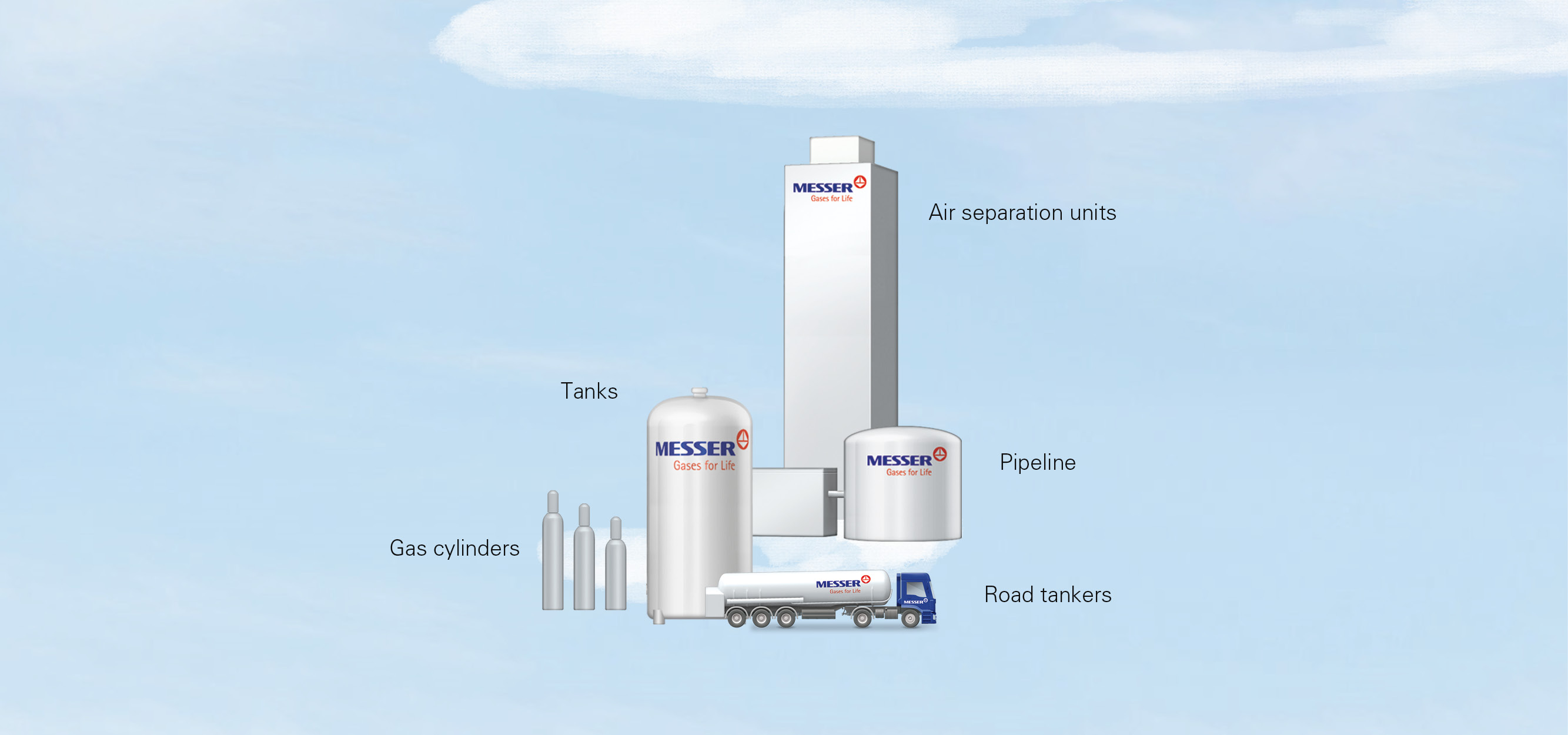

In smaller quantities, gases are stored in gas cylinders. When industrial gases are needed in large quantities, we install tanks at our customer’s plant. These tanks are used to store gases such as oxygen, nitrogen, argon or CO2 in liquid form. Road tankers are used to transport the gas from the production plants to the customer.

Major industrial concerns such as steel works or chemical companies need so much gas that they often have an air separation unit operating on their grounds. Sometimes pipelines also supply gases to one or more major facilities, such as in industrial parks.

The greater the quantity of gases a consumer needs, the shorter the distance should be between the customer’s site and the location where the gases are being produced. Generally speaking, gases are produced where they are needed: close to densely developed industrial areas.

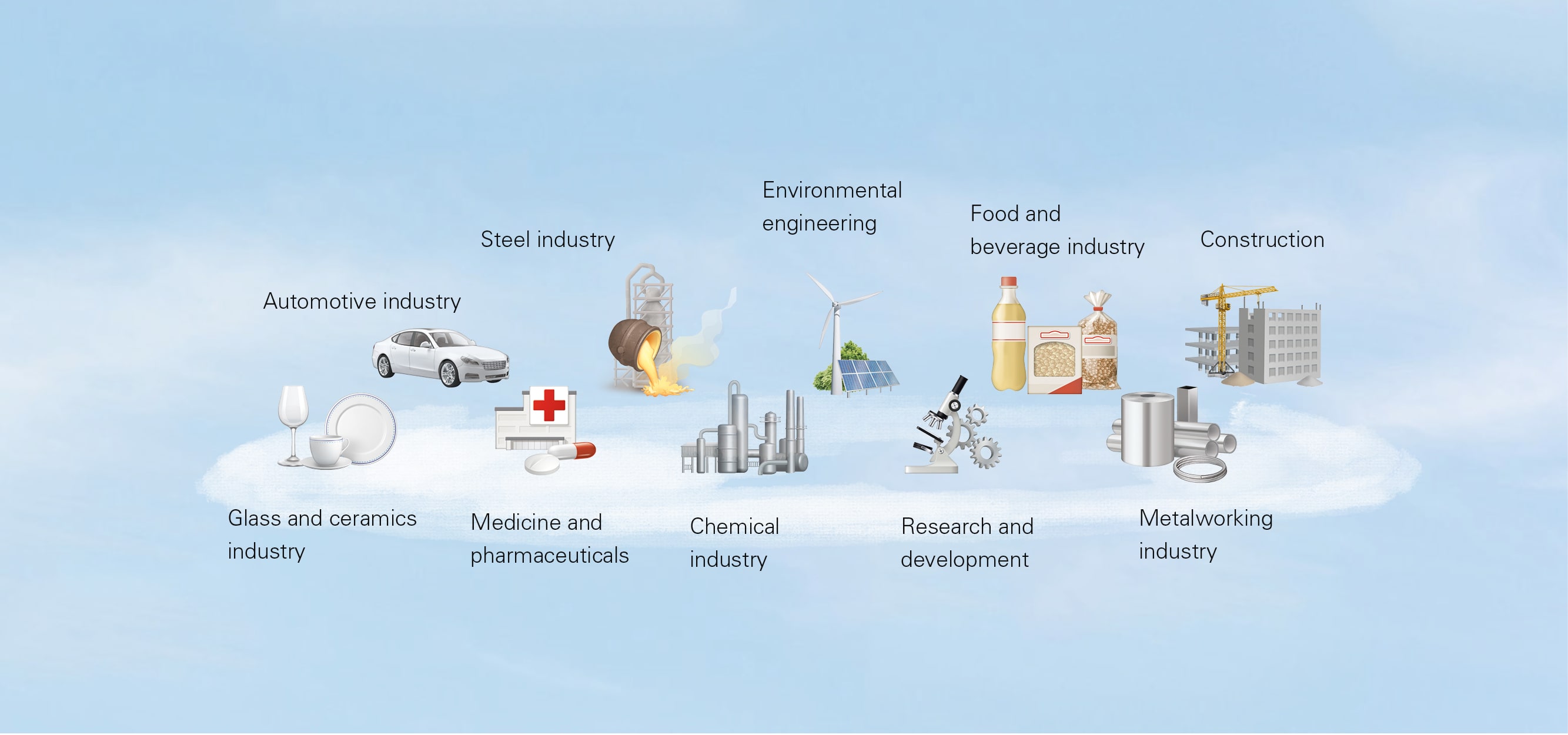

Industrial gases are used in a variety of purity grades and for a wide range of purposes. Including as food gases and medical gases. Industrial gases can make production processes safer and more cost-effective and improve product quality. They often contribute to environmental protection. Some processes and applications would even be inconceivable without the chemical properties of gases. Typical user sectors include the automotive industry, the steel industry, environmental engineering, food and beverages, construction, metallurgy, glass and ceramics, medicine and pharmaceuticals, the chemical industry, and research and development.